In the world of electronics manufacturing, achieving the right production scale is crucial for maintaining both efficiency and cost-effectiveness. Mid-volume PCB assembly stands out as the ideal solution for companies that have moved beyond the prototype phase but are not yet ready for full-scale mass production. It bridges the gap between low-volume and high-volume assembly, offering the flexibility, precision, and scalability modern electronic businesses demand.

Understanding Mid-Volume PCB Assembly

Mid-volume PCB assembly refers to the production of printed circuit boards in moderate quantities—typically ranging from a few hundred to several thousand units. It is the preferred choice for companies testing the market for new electronic products or managing regular but not massive production runs. This process ensures consistent quality and reliable turnaround times without the logistical challenges and costs associated with high-volume manufacturing.

Unlike prototype assembly, where the focus is on design validation, mid-volume assembly prioritizes repeatability and optimization. It leverages automated systems and refined processes to achieve higher efficiency while maintaining tight quality control standards.

Key Features of Mid-Volume PCB Assembly

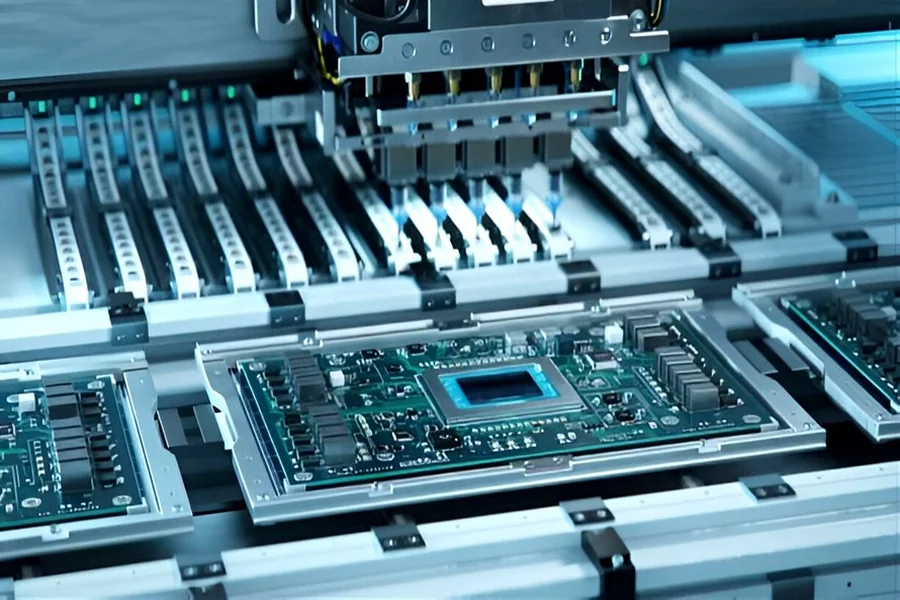

One of the defining characteristics of mid-volume PCB assembly is its balance between flexibility and automation. It combines advanced technologies such as automated pick-and-place machines, surface-mount technology (SMT), and automated optical inspection (AOI) to ensure accuracy and consistency.

The process typically includes several critical steps: solder paste printing, component placement, reflow soldering, inspection, and functional testing. Each stage is optimized to deliver repeatable results that meet stringent industry standards. Manufacturers who specialize in mid-volume assembly also emphasize efficient material management, allowing seamless transitions between small and large-scale production.

Benefits of Mid-Volume PCB Assembly

There are several compelling reasons why companies choose mid-volume PCB assembly for their projects. It provides a unique combination of speed, cost-efficiency, and quality that is difficult to achieve with other production scales.

The biggest advantage is cost optimization. By leveraging automated processes while keeping overheads manageable, manufacturers can offer competitive pricing without compromising quality. Furthermore, it allows companies to adjust production volumes quickly, responding to changes in demand or design revisions without major disruptions.

Quality assurance is another major benefit. Because mid-volume assembly relies on semi-automated testing and inspection systems, manufacturers can identify potential issues early in the process. This proactive approach minimizes defects and ensures consistent performance across all units.

Applications of Mid-Volume PCB Assembly

Mid-volume PCB assembly is widely used across industries that require high-quality electronic components in moderate quantities. It is particularly common in sectors such as industrial automation, automotive electronics, telecommunications, and medical devices.

For instance, companies developing specialized communication equipment or control systems may need regular production batches without committing to the scale and expense of high-volume manufacturing. Similarly, medical device manufacturers often rely on mid-volume assembly to maintain consistent quality in sensitive and regulated environments.

This production scale is also ideal for OEMs (Original Equipment Manufacturers) and startups that are transitioning from prototype validation to steady market supply. It provides a flexible and reliable pathway for scaling production while maintaining financial control.

Quality and Precision in Mid-Volume PCB Assembly

In mid-volume PCB assembly, quality assurance is not an afterthought—it is embedded in every step of the process. Advanced inspection methods, including automated optical inspection (AOI), X-ray analysis, and in-circuit testing (ICT), are used to detect soldering defects, misaligned components, and connectivity issues.

Additionally, manufacturers implement statistical process control (SPC) to monitor production metrics in real time, ensuring that every batch meets performance expectations. Consistency is key, and each unit undergoes rigorous testing to verify its compliance with customer specifications and international quality standards such as ISO 9001 and IPC-A-610.

Why Choose Mid-Volume PCB Assembly for Your Next Project

Choosing mid-volume PCB assembly offers significant advantages in terms of scalability and efficiency. It enables companies to maintain control over production costs while still benefiting from the precision and speed of advanced manufacturing technologies.

Another benefit is the ability to refine designs based on real-world feedback before committing to full-scale production. This iterative approach reduces the risk of design flaws and ensures that final products are optimized for performance and manufacturability.

Moreover, mid-volume assembly provides greater supply chain flexibility. Manufacturers can source components strategically and schedule production runs that align with business goals, reducing inventory waste and lead times.

Conclusion

In today’s competitive electronics market, mid-volume PCB assembly offers the perfect balance between innovation, efficiency, and affordability. It supports manufacturers and product developers who need consistent production quality without the complexities of high-volume manufacturing. By combining automated precision with adaptable production workflows, mid-volume assembly ensures that electronic products are delivered on time, within budget, and to the highest standards.

If you are seeking reliable and scalable PCB assembly services for your next project, partnering with an experienced provider can make all the difference. A trusted assembly partner will help streamline your production process, ensure quality consistency, and deliver cost-effective solutions tailored to your requirements—empowering you to bring your products to market faster and more efficiently.